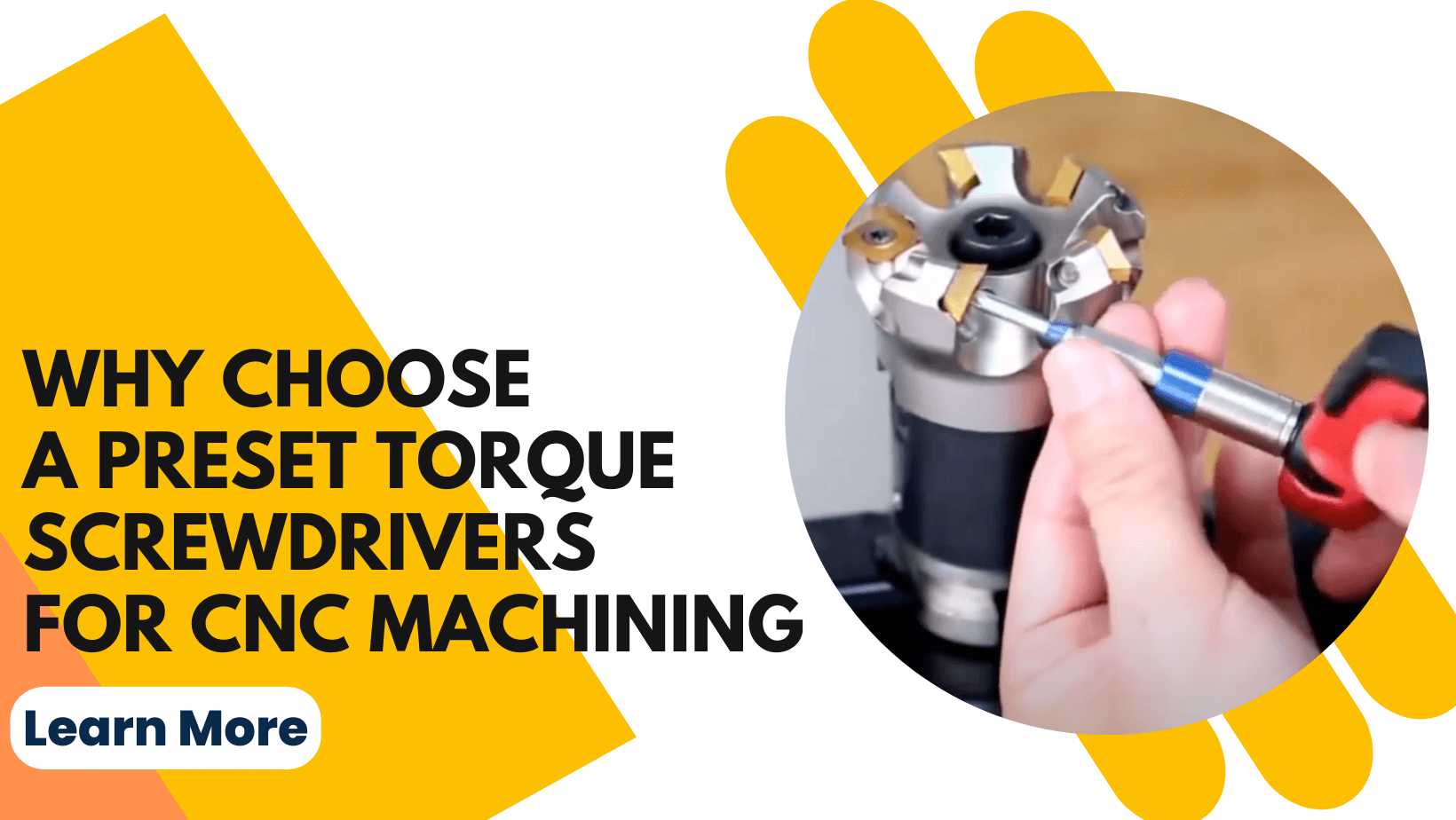

In the precise world of CNC machining, tool optimization is essential. Torque screwdrivers, vital for maintaining machinery performance, underscore the importance of precise torque application in ensuring smooth and efficient operations. Let’s dive into why a preset torque screwdriver is not merely a tool, but rather a game changer in the CNC industry.

The Importance of an Efficient Tool with the Correct Torque

In CNC machining, efficient and accurate tool changes are paramount. Using the correct torque setting ensures tool longevity and work quality. Two common tools for this purpose are adjustable and preset torque screwdrivers.

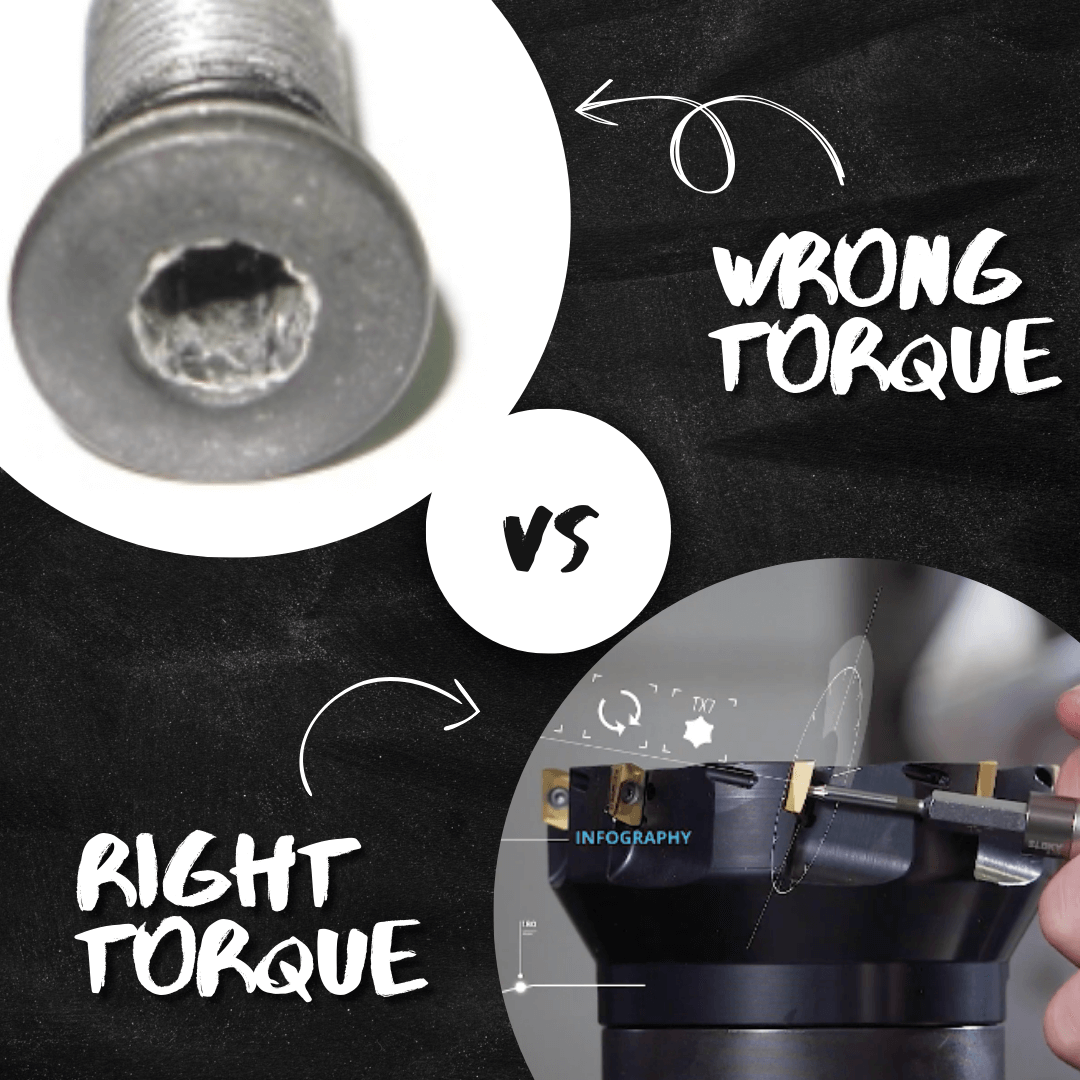

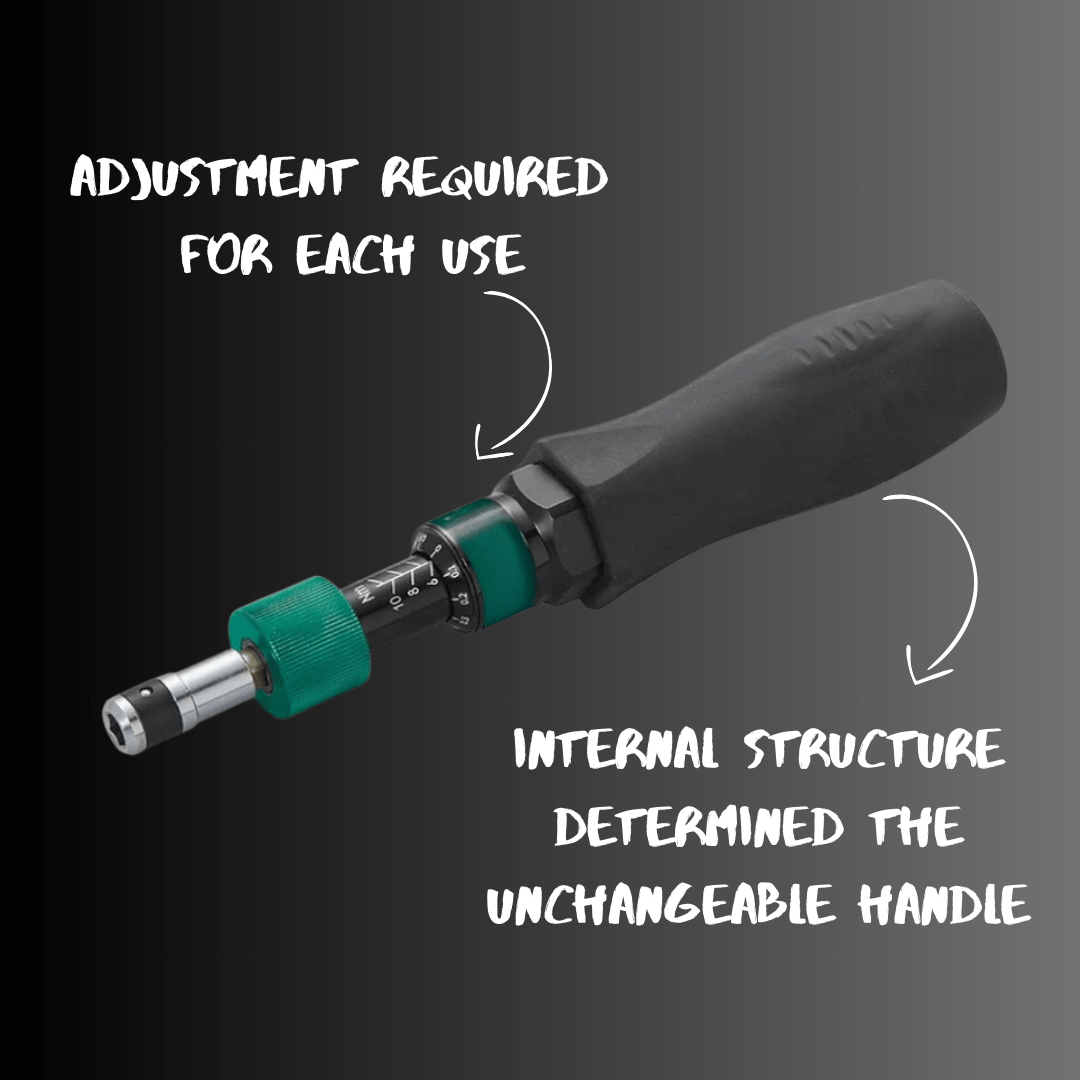

Benefits and Drawback of Adjustable Torque Screwdrivers

Adjustable torque screwdrivers offer versatility but present challenges. Their spring mechanism requires manual adjustment for each use, consuming valuable time and introducing potential for error in a fast-paced CNC environment where time and accuracy are paramount.

Benefits and Drawbacks of Preset Torque Screwdrivers

Preset torque screwdrivers excel in ease of use and reliability. Set to deliver a specific torque, they allow immediate operations, requiring no adjustments. However, traditional models can be expensive, requiring the purchase of multiple screwdrivers for different torque settings.

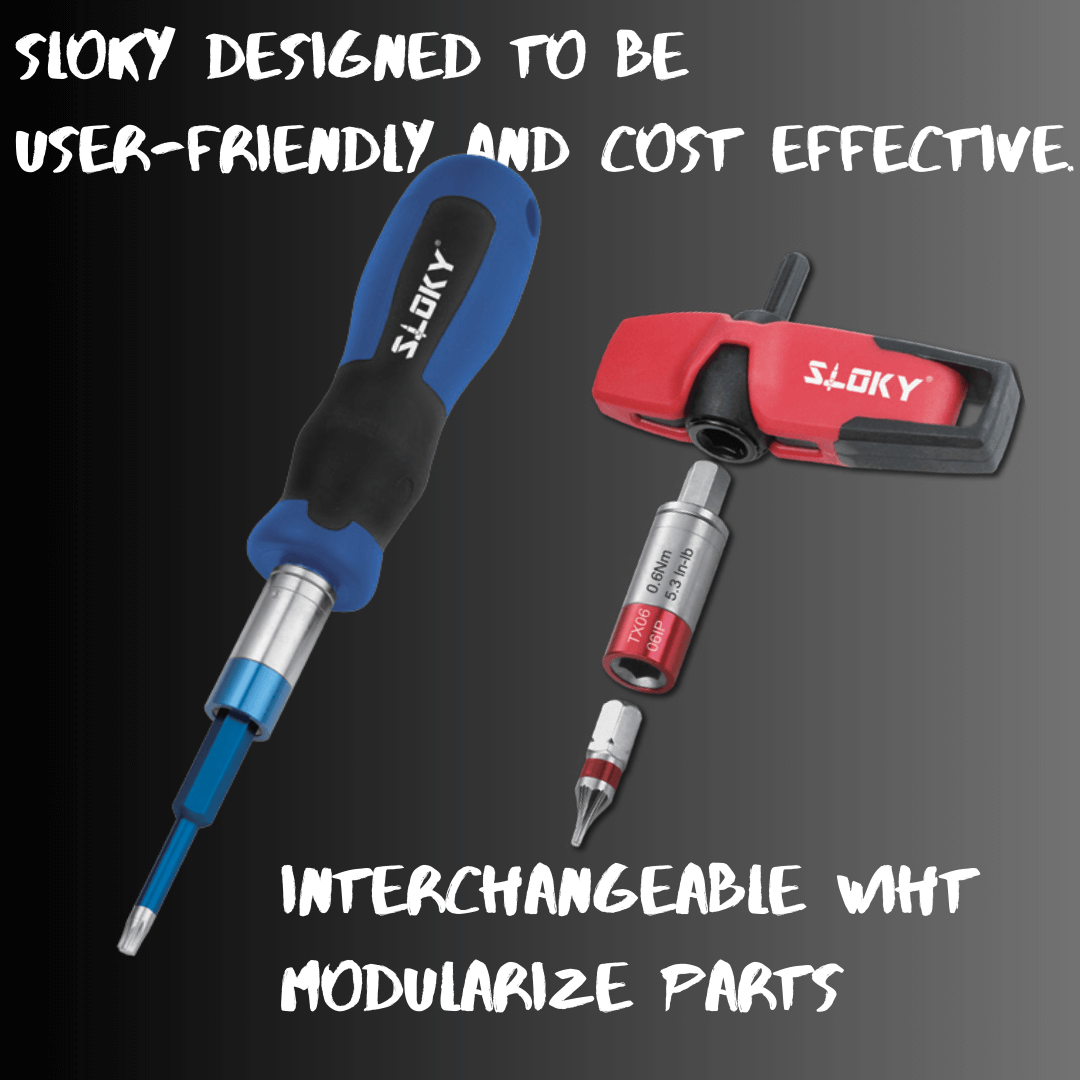

SLOKY’s Innovative Design

SLOKY addresses these challenges with its innovative preset torque screwdrivers. SLOKY’s modular design allows users to switch between torque settings without needing multiple tools, providing a cost-effective solution. The unique color-coded system simplifies tool selection, further enhancing efficiency.

Conclusion

Preset torque screwdrivers are indispensable in CNC machining, streamlining processes, enhancing precision, and reducing errors. SLOKY’s unique approach combines convenience, efficiency, and affordability, setting a new industry benchmark. Investing in SLOKY torque screwdrivers is a strategic move towards optimizing CNC machining operations for both seasoned machinists and newcomers.