The exponential growth in artificial intelligence (AI) applications has significantly increased the demand for high-performance server CPUs. Data centers across the United States are rapidly expanding to accommodate AI workloads, machine learning algorithms, and big data analytics. This unprecedented demand has placed a spotlight on the importance of efficient and reliable Server Cpu Heatsink Installations.

The Necessity of Cooling Solution for Quality Server CPUs

A quality server CPU demands an equally robust cooling solution. In the competitive landscape of data center hardware, thermal management plays a pivotal role in maintaining peak performance. Two primary cooling methods dominate the market:

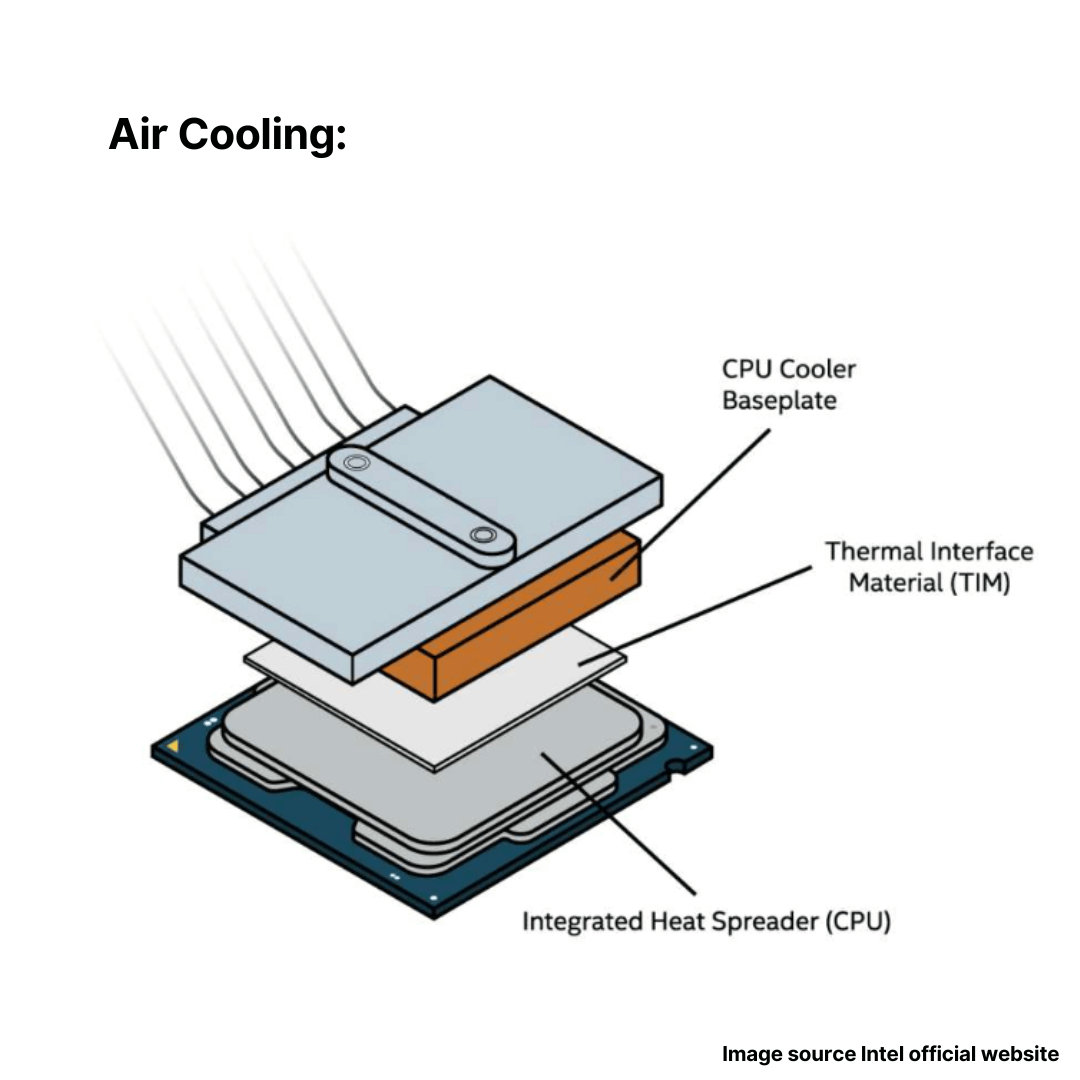

- Air Cooling:

Air cooling systems rely on fans and heatsinks to dissipate heat from the CPU. They are cost-effective and simpler to install, making them a popular choice for many applications. However, even in air-cooled systems, precise torque control is essential to ensure that the heatsink makes uniform contact with the CPU, maximizing heat transfer efficiency.

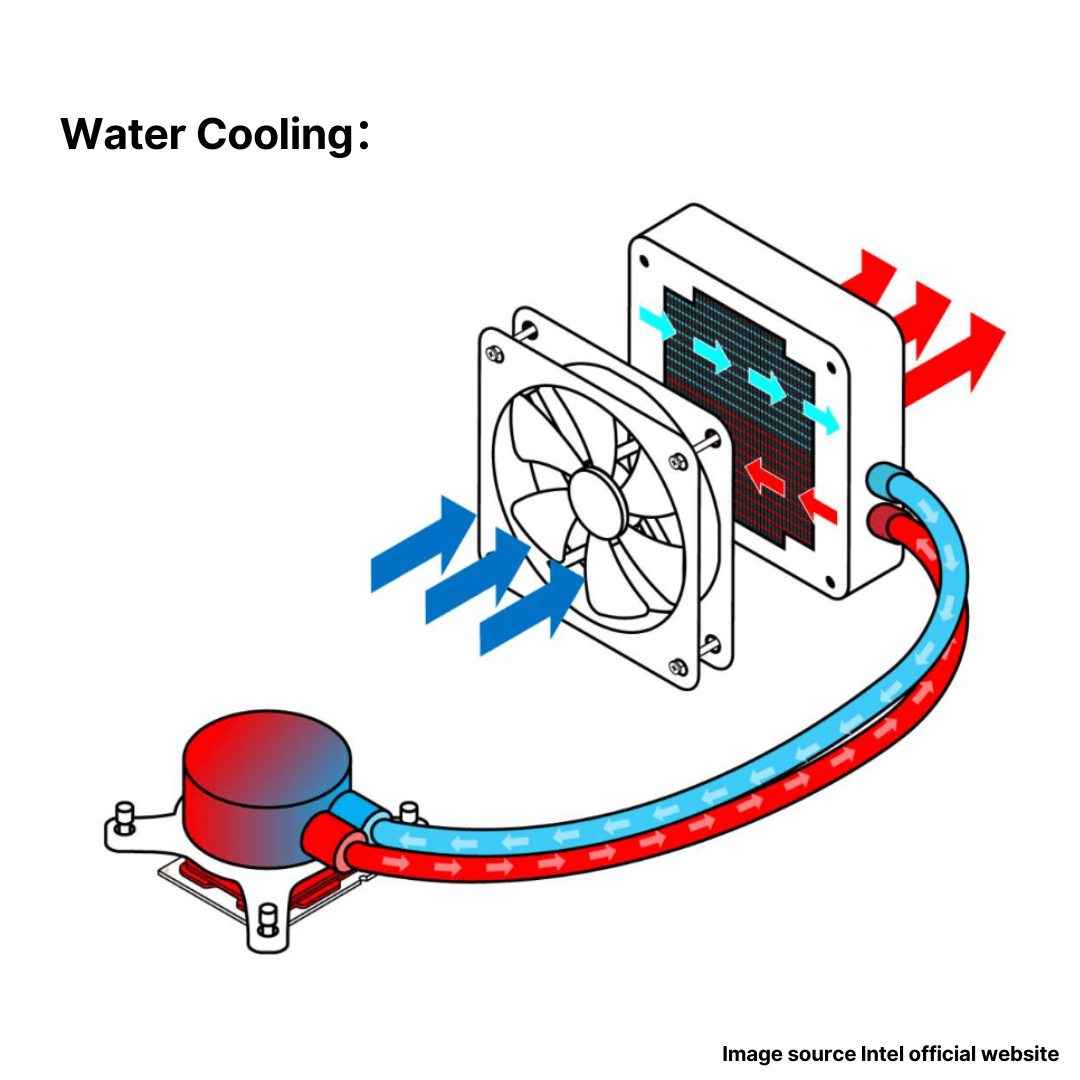

- Water Cooling:

Water cooling offers superior heat dissipation by circulating coolant directly over a heatsink attached to the CPU. This method can handle higher thermal loads, but it requires meticulous installation to avoid leaks and ensure that the cooling components operate effectively. Precise torque control becomes even more critical here, as uneven pressure can compromise the sealing of water blocks or lead to improper contact between the cooling head and the CPU.

Regardless of the chosen method, the common denominator is the need for a secure and evenly distributed connection between the CPU and its heatsink. In Server Cpu Heatsink Installations, the challenge lies in achieving a uniform interface that minimizes thermal resistance while preventing issues such as stripped screws or uneven pressure distribution—a problem that can ultimately result in catastrophic component failure.

The Science Behind Even Pressure Distribution

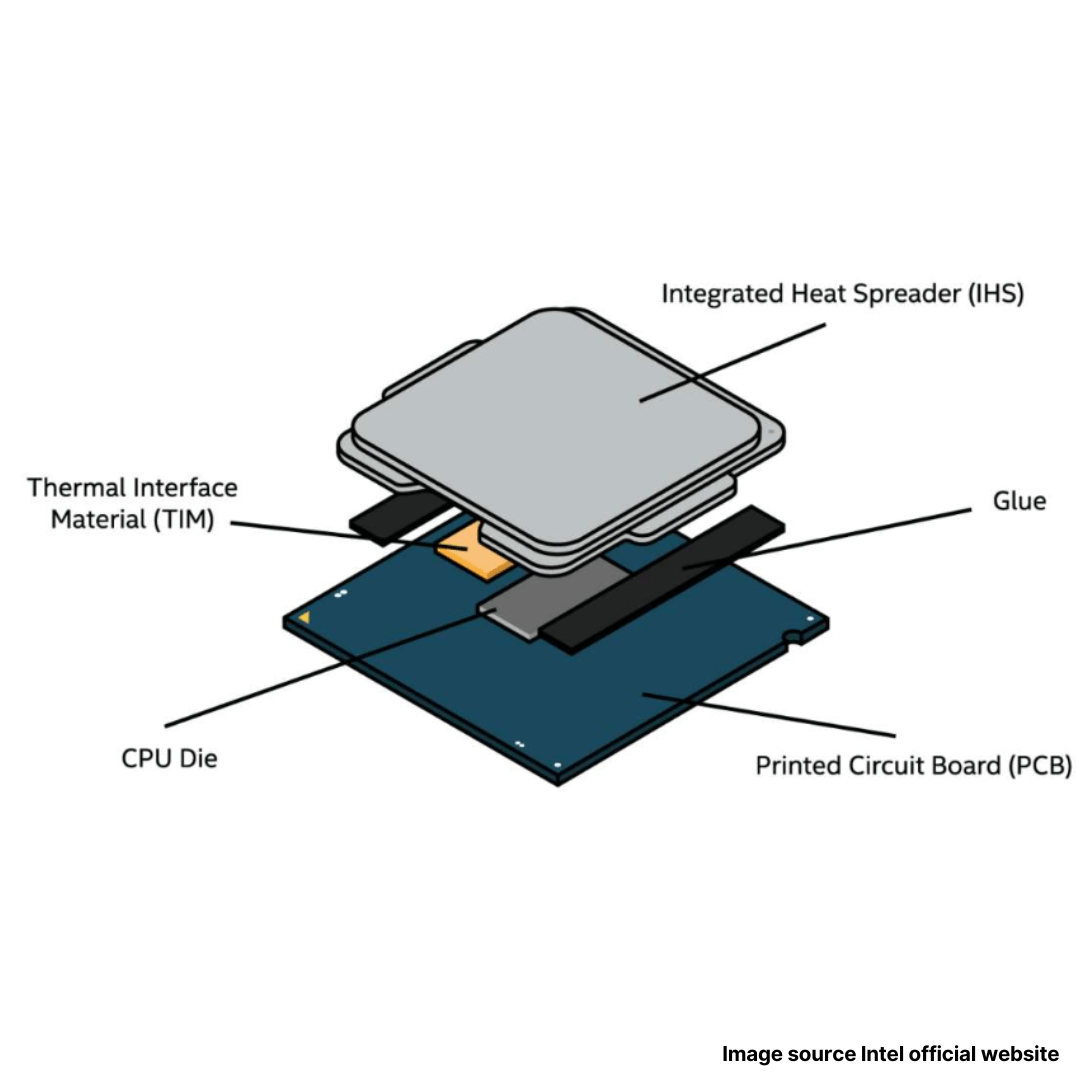

Every successful Server Cpu Heatsink Installation depends on achieving an even and stable contact between the CPU’s integrated heat spreader (IHS) and the heatsink. Unlike idealized systems, the heat generated within a CPU is not uniformly distributed. Modern CPUs contain multiple cores, caches, and various other modules that produce heat at different intensities. To mitigate these variations, CPUs are designed with an IHS—a metal plate that helps disperse the heat over a larger area.

-

Heatsink Design and Contact Area:

Whether using air or water cooling, the heatsink must be engineered to cover the entire IHS. A well-designed heatsink maximizes the contact area, ensuring that all parts of the IHS contribute to heat dissipation. The flatness of the heatsink’s bottom surface is critical; any imperfections can lead to gaps that hinder thermal transfer.

-

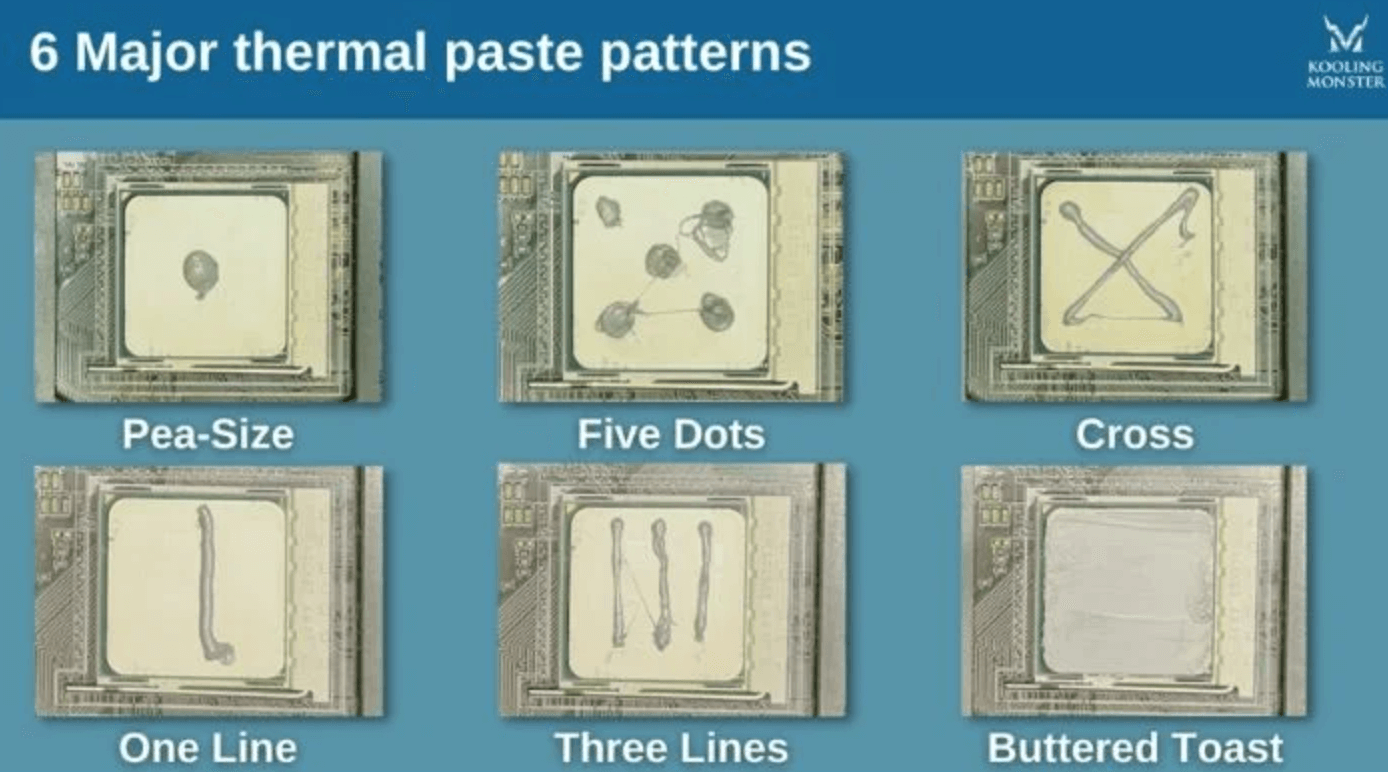

Application of Thermal Paste:

Thermal paste plays an essential role in filling microscopic imperfections between the CPU and the heatsink. The proper amount of thermal paste ensures that any remaining air gaps are minimized, facilitating a more uniform and efficient heat transfer process. -

Even Pressure Distribution:

One of the most challenging aspects of installation is applying the right amount of pressure uniformly across the CPU’s surface. For both Intel and AMD systems, uneven locking force during installation can lead to insufficient contact in some areas, resulting in hot spots. These hot spots are regions where the temperature exceeds safe operational thresholds, potentially triggering thermal throttling and degrading CPU performance.

Best Practices for Proper Heatsink Attachment

Properly securing the heatsink is an art that balances technical precision with practical execution. For IT professionals tasked with Server Cpu Heatsink Installations, following a structured and methodical approach is essential:

-

-

Heatsink Placement:

Begin by aligning the heatsink’s metal conduction surface (often referred to as the cold plate) with the CPU’s IHS. For water cooling systems, additional considerations include the orientation of water pipes, the position of fans, and ensuring that the water block’s marked direction aligns correctly with the CPU layout. -

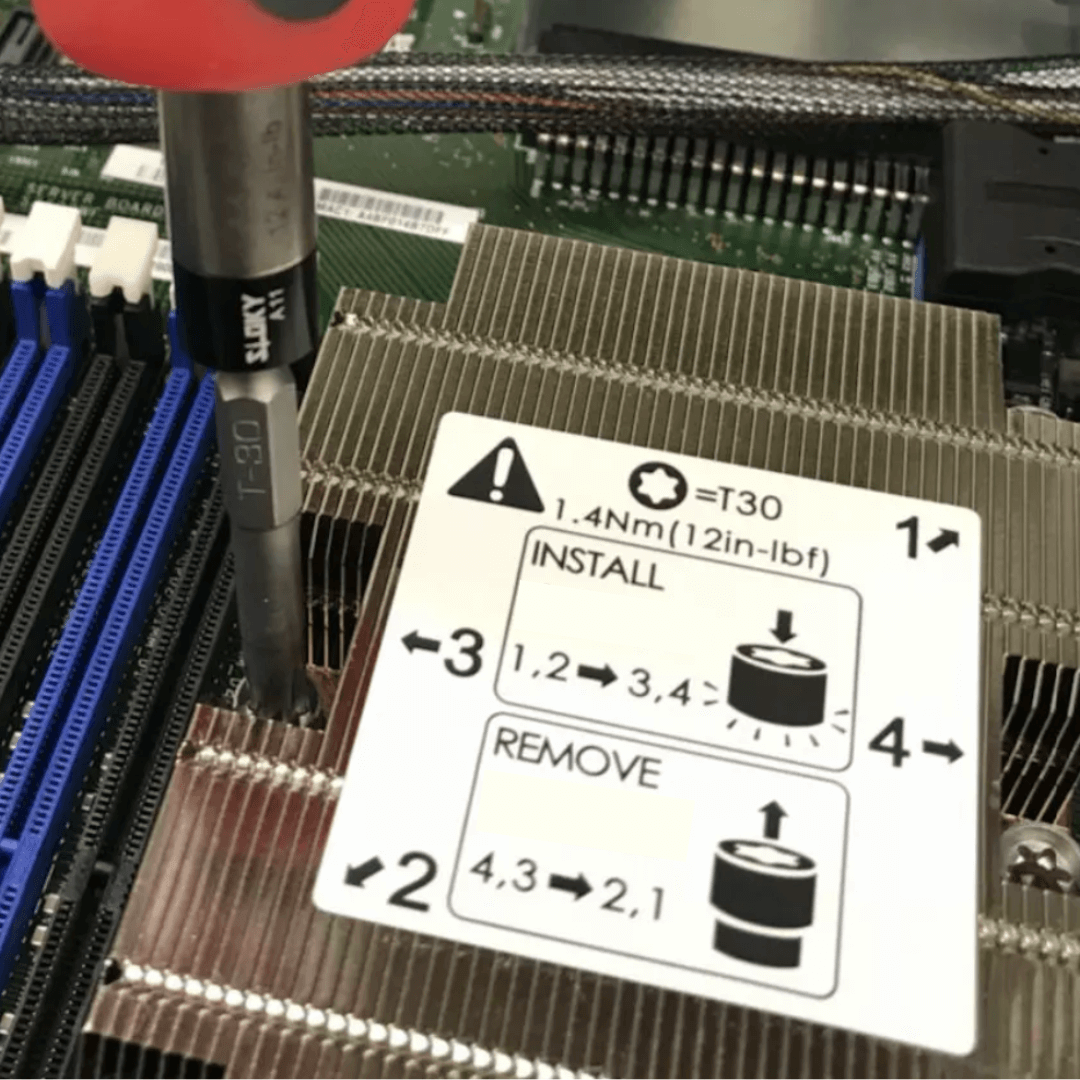

Diagonal Tightening Sequence:

Most heatsinks come with multiple screws or retention clips. It is advisable to use the manufacturer’s recommended sequence for tightening these fasteners. Typically, start by hand-tightening each screw just enough to catch the threads, then follow a diagonal pattern to gradually apply pressure. This cross-tightening technique ensures that the force is distributed evenly across the CPU surface, reducing the risk of uneven pressure that might lead to poor thermal contact. -

Controlled Torque Application:

Many heatsinks specify a torque value (for example, 1.2 Nm) to ensure optimal contact without over-tightening. Utilizing a torque screwdriver can help achieve this precision. By setting the appropriate torque value, engineers can eliminate the risk of over-compressing the thermal paste or damaging the IHS due to excessive force.

-

Protecting CPU Integrity with SLOKY’s Precision Torque Tools

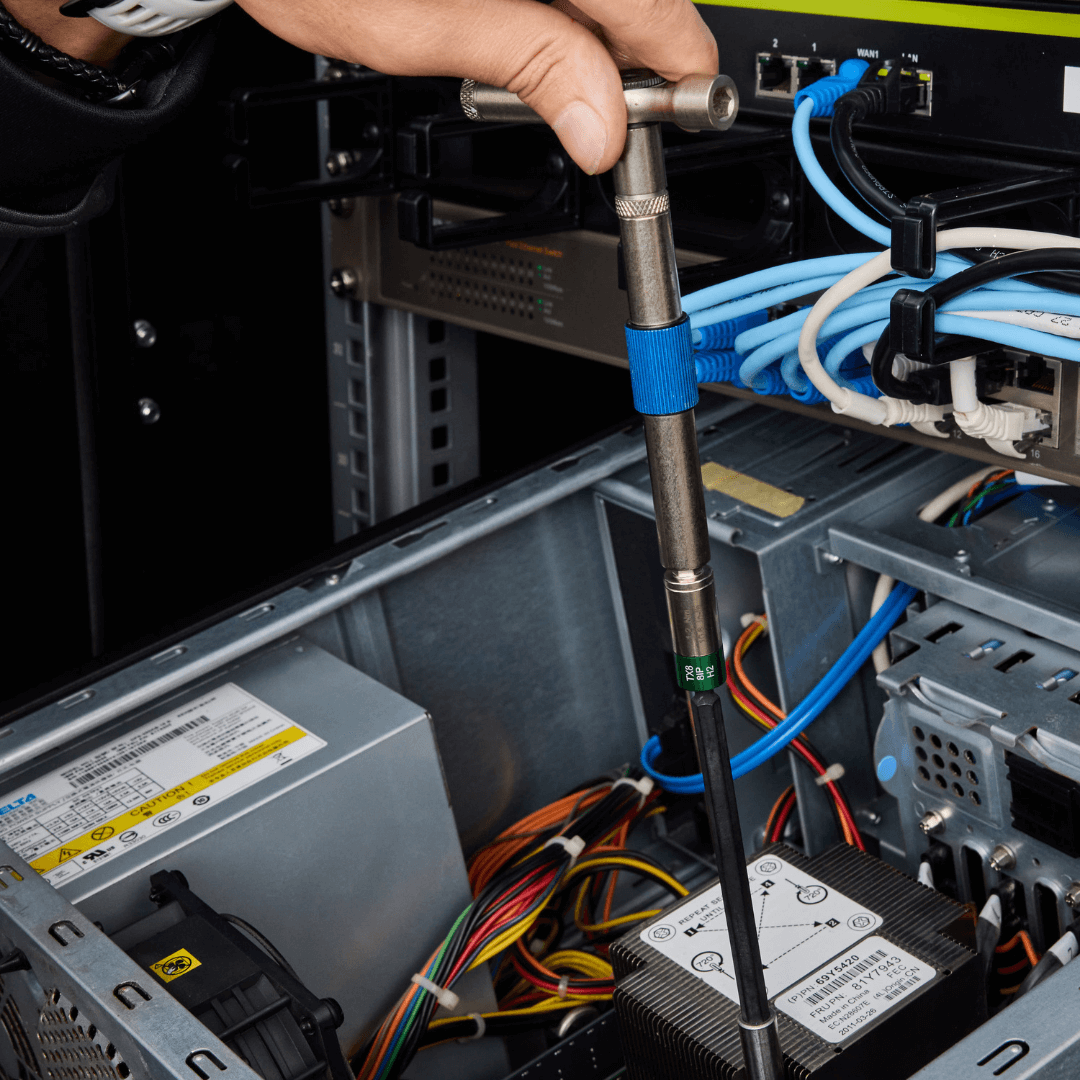

n large-scale data centers, particularly those powering AI-driven applications, every CPU’s performance is critical. With thousands of CPUs installed, each requiring hundreds of fasteners, the cumulative impact of even minor installation errors can be enormous. This is where SLOKY’s state-of-the-art torque tools make a decisive difference.

Key advantages of using SLOKY’s tools include:

-

-

Patent-Pending Precision:

SLOKY’s innovative design modularizes the torque application process, ensuring that every fastener in Server Cpu Heatsink Installations is tightened with consistent precision. This patented approach allows SLOKY tools to adapt to various heatsink designs and CPU configurations, delivering the exact torque required for optimal contact. -

Enhanced Operational Efficiency:

By employing SLOKY’s torque tools, data center technicians can significantly reduce installation time while eliminating the risk of uneven pressure distribution. The intuitive design of the tool simplifies the entire process, making it accessible even for less experienced personnel without compromising on quality. -

Comprehensive Quality Assurance:

With SLOKY, precision isn’t just about meeting torque specifications—it’s about ensuring long-term reliability. The tools are rigorously tested and calibrated to deliver consistent results across multiple installations. This means that whether it’s a single server rack or an entire data center, every CPU is secured in a manner that minimizes thermal risks and maximizes performance. -

Scalability for Data Centers:

Consider an AI data center with tens of thousands of CPUs. The cumulative benefit of using SLOKY’s torque tools is substantial. By standardizing the installation process with precise torque control, data center operators can ensure that every screw contributes to a stable thermal interface, ultimately protecting critical infrastructure and reducing the likelihood of downtime due to overheating. -

Tailored to the U.S. Market:

SLOKY understands the unique demands of the American data center market. Our tools are engineered to meet stringent quality standards, ensuring that each Server Cpu Heatsink Installation is performed with a level of precision that American companies expect from world-class technology providers.

-

In conclusion, the integration of SLOKY’s torque tools in Server Cpu Heatsink Installations not only secures CPU integrity but also plays a crucial role in maintaining the efficiency and longevity of data centers. By leveraging precise torque control and user-friendly operation, SLOKY provides the industry with the confidence that every installation meets the highest standards of safety and performance.