Stripped screws frequently trouble DIY enthusiasts, technicians, and industrial operators. Common causes include over-tightening, incorrect tools, and soft or incompatible screw materials. Stripped screws lead to challenging removals, potential equipment damage, increased maintenance costs, and compromised safety, especially in precision tasks like CNC machining, automotive repairs, and medical device assembly.

Proven Methods for Removing Stripped Screws

Depending on severity, effective removal methods include:

- Rubber band method: Increases grip by placing a rubber band over the screw.

- Specialized screw extractors: Designed specifically for efficient screw removal.

- Reverse drill bits: Ideal for severely stripped screws.

- Thread re-tapping: Necessary when damage is extreme.

How to Prevent Screw Stripping

Prevention is better than cure. Recommended preventive measures:

- Correct tightening methods: Precisely control torque.

- Appropriate screw selection: Match screws to materials.

- Avoid manual over-tightening: Apply moderate force.

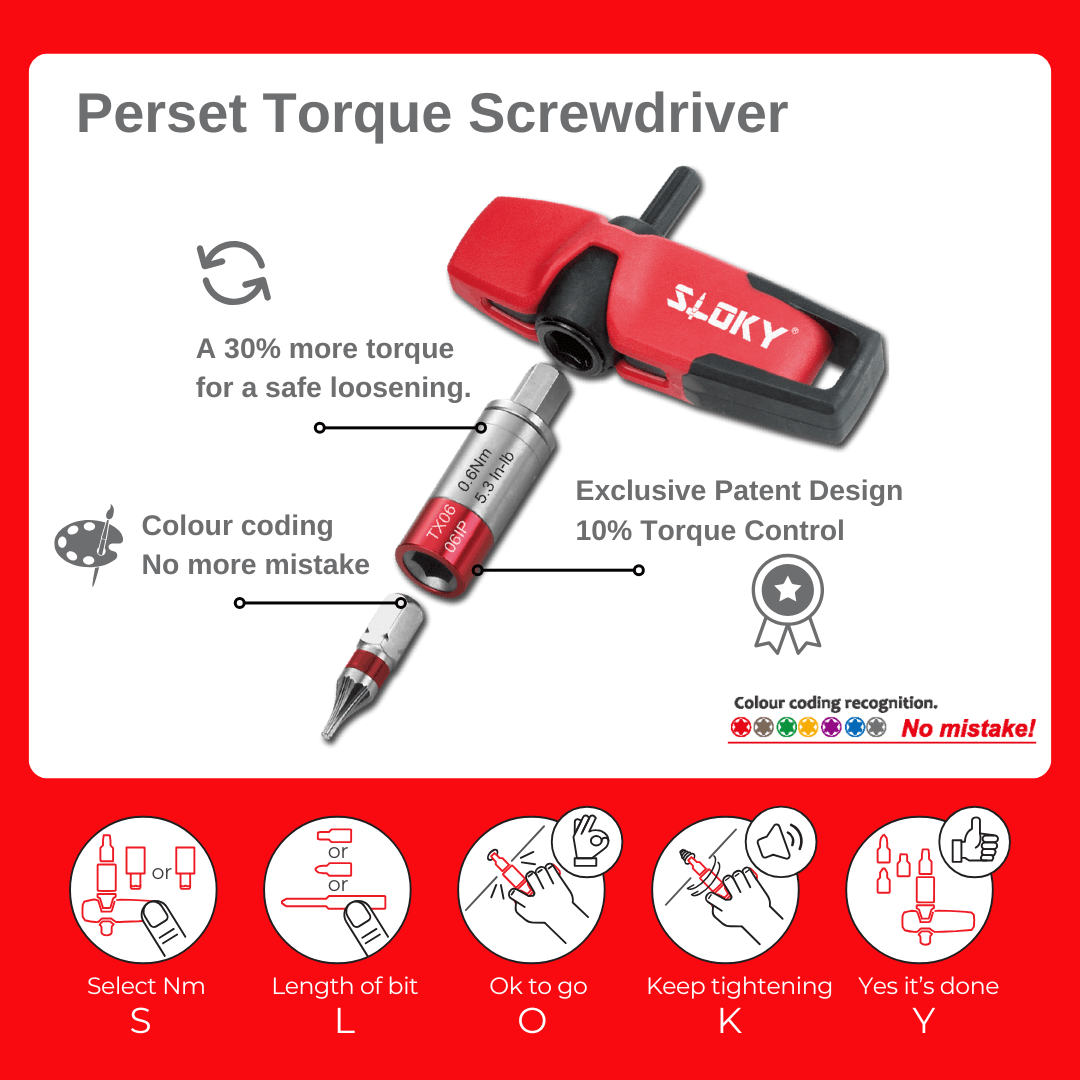

- Use precision torque tools: Ensure optimal tightening.

SLOKY Torque Tools: Professional Solutions

SLOKY torque tools are specifically designed to address stripped screws, suitable for CNC machining, automotive repair, and medical assembly. Features include:

- Precise torque control to prevent over-tightening.

- Enhanced safety and efficiency.

- Durable, high-quality design meeting international standards.

- Versatile product range catering to diverse industries.

Reliable Connections, Every Time

With effective removal methods and preventive strategies, effortlessly resolve stripped screws issues. Choose SLOKY torque tools for precision, reliability, and superior productivity.

SLOKY Torque Tools – Precision Control, Reliable Connections, Every Time.