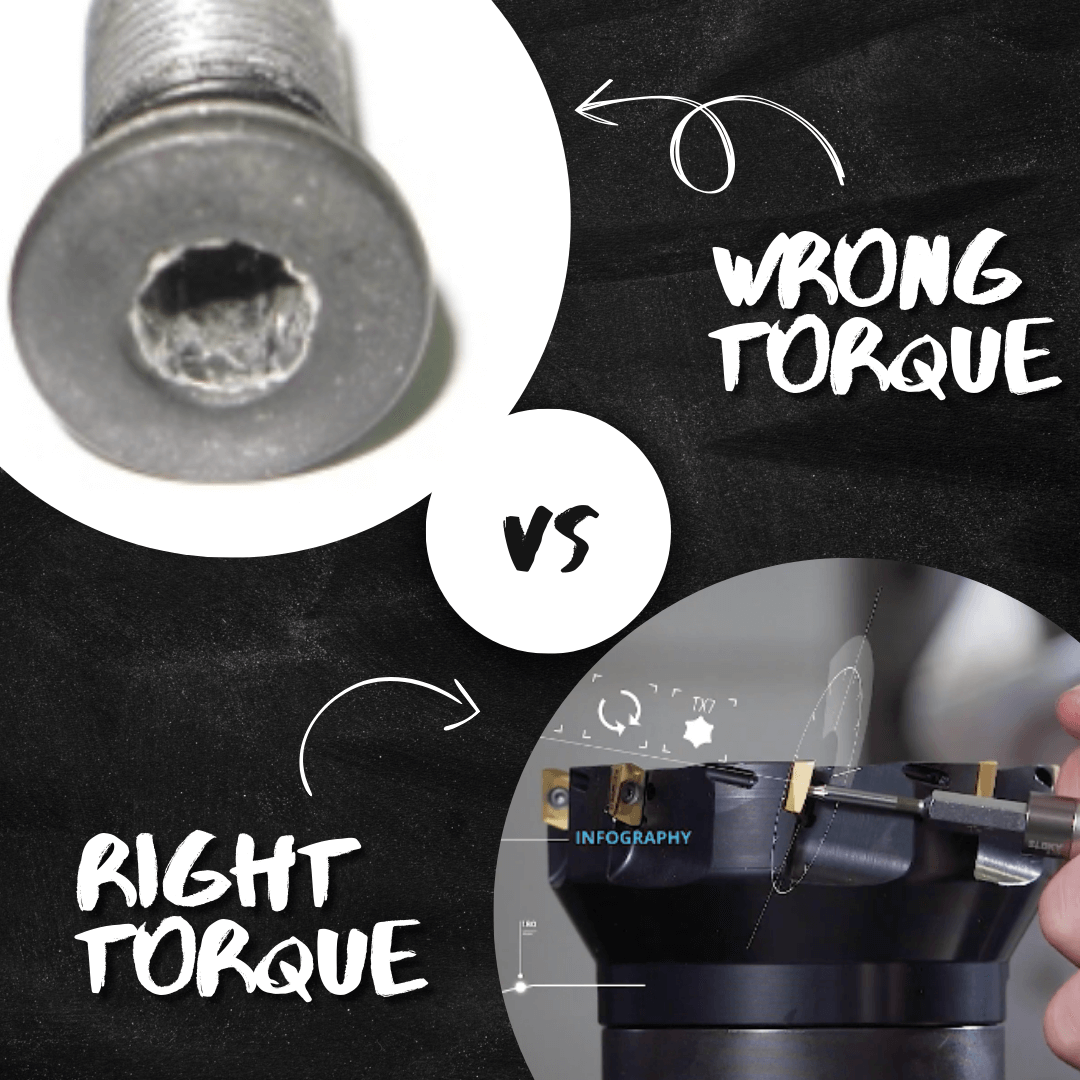

Traditional wrenches for CNC tool changes often lead to serious problems, with stripped screws being one of the most frustrating issues. Once a screw is stripped, it takes significant time to remove it, leading to production inefficiencies and potential machine damage.

Using a torque tool ensures that the correct force is applied when tightening screws, preventing over-tightening or under-tightening issues. This improves overall machining precision and extends the lifespan of both screws and tools, ultimately boosting productivity and reducing downtime.

How to Ensure the Correct Torque Value?

Each screw type requires a specific torque value, which is standardized across the industry. Using the correct torque setting addresses two major issues:

- Under-tightening: Loose screws cause vibration during machining, leading to poor cutting performance and subpar finishes.

- Over-tightening: Excess torque strips screws, which can damage expensive CNC equipment.

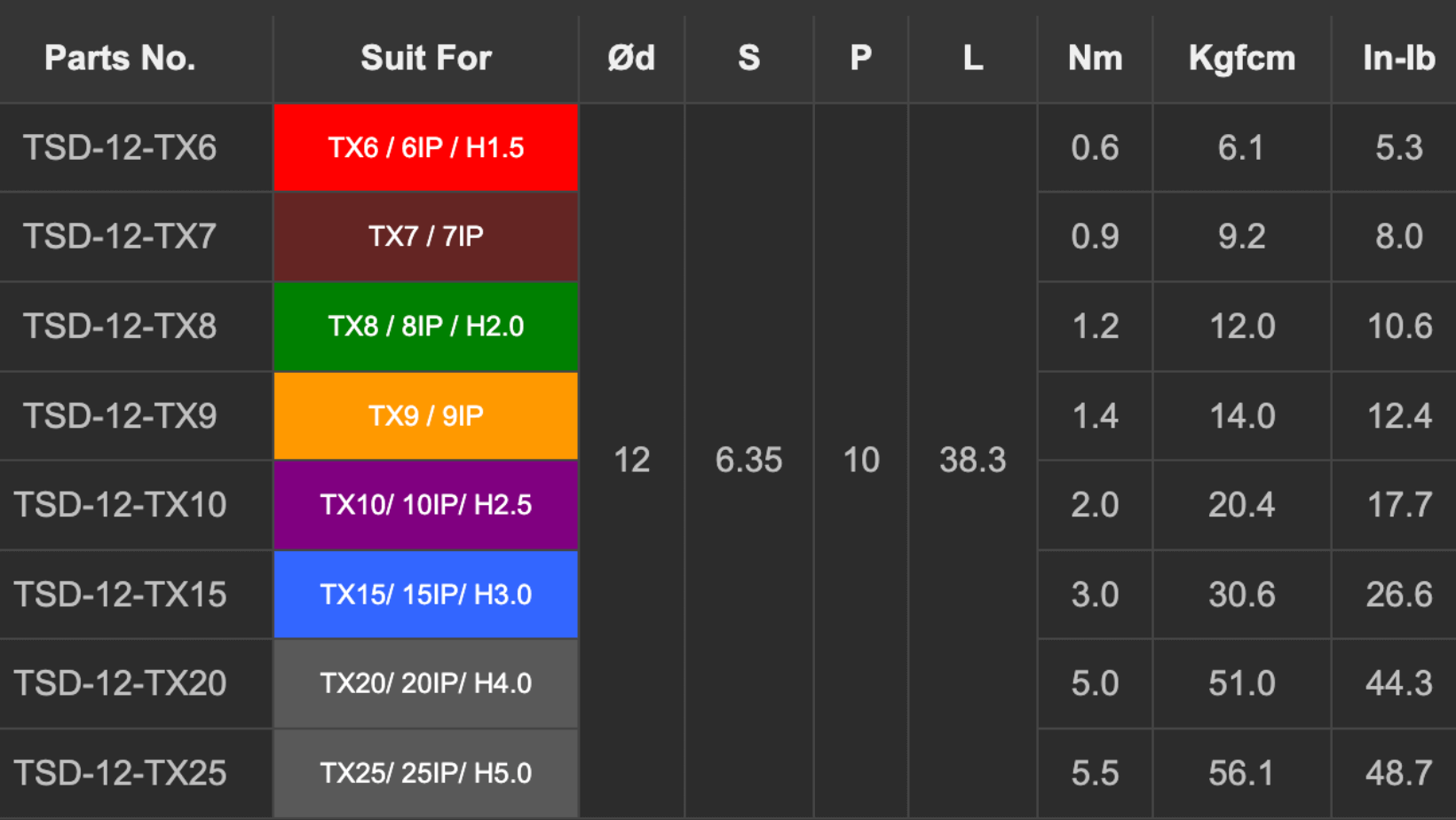

To help CNC professionals, SLOKY has compiled a reference guide for the most commonly used screws in the CNC industry, including TX, IP, and HX series screws, ensuring that every tool change is performed with precision.

Why SLOKY is the torque screwdriver for CNC machine

SLOKY torque tools are specifically designed for CNC applications. They feature a preset torque mechanism, eliminating the need for frequent adjustments and calibrations. The TX6-TX25 torque range covers the most commonly used torque values in CNC machining.

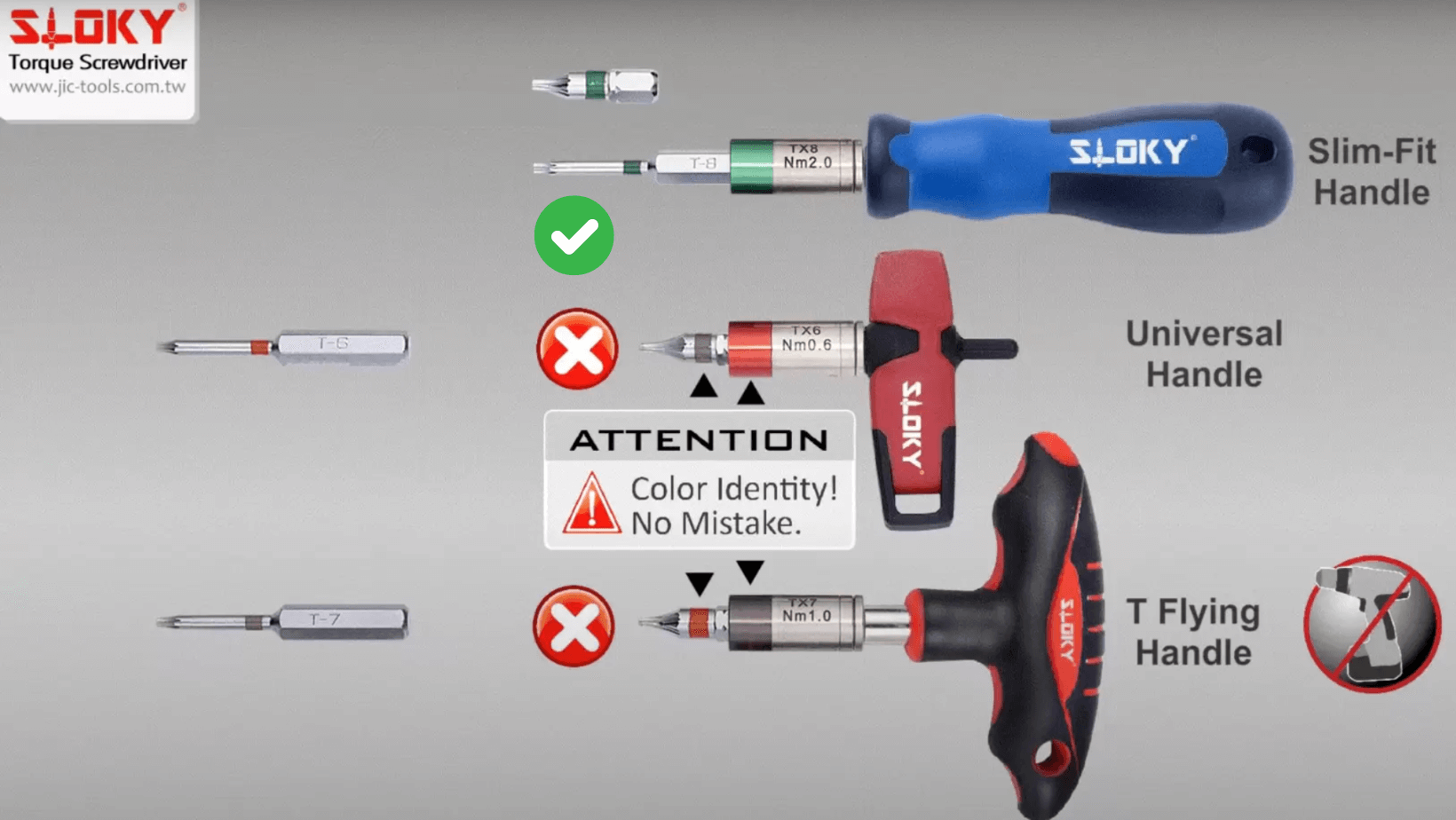

Color Management System

We continuously emphasize the importance of using the correct torque, but what matters most is ensuring the correct torque setting is applied every time.

For example, if a 3Nm torque setting is required but a 5Nm torque tool is mistakenly used, the user will tighten the screw until they hear the click, which may already be causing damage. In this case, using the wrong torque tool can be worse than not using one at all.

To solve this issue, SLOKY has introduced a Color Management System in its design. Each torque driver is color-coded to match the corresponding bits, making it easy to identify the correct tool at a glance.

Example: A red torque adapter pairs with a red bit, ensuring immediate recognition TX6.

This simple color-coded system prevents errors and ensures that every fastening operation is performed accurately and efficiently. Using the correct torque tool prevents screw damage, extends tool life, and reduces the risk of machine downtime.

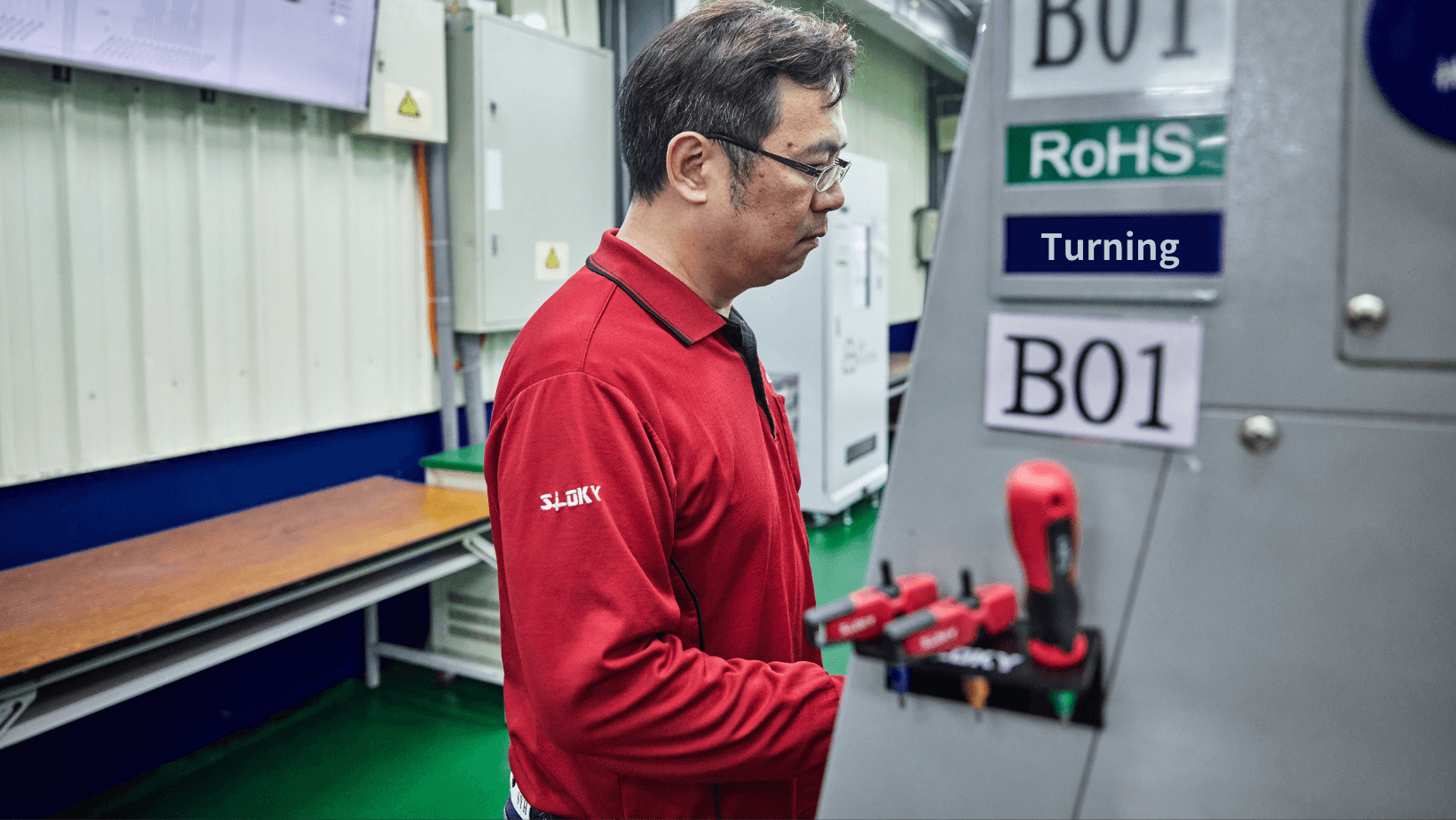

Real-World Applications

To maintain the highest quality standards, SLOKY’s components are manufactured using precision CNC machining. In real CNC production environments, professionals rely on the SLOKY Display Set to streamline tool changes and maximize efficiency.

By integrating SLOKY torque tools into your workflow, your team can minimize errors, reduce maintenance costs, and ensure consistent machining performance.